7S for the Real World

September 25, 2025

Why 5S Matters

5S is one of the simplest and most powerful Lean tools. It organizes the workplace so teams can see problems, work efficiently, and keep improvements in place.

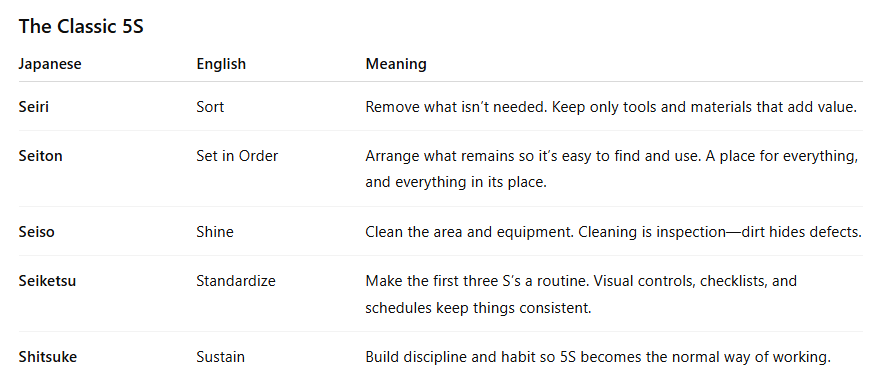

The method started in Japan, and each "S" comes from a Japanese word. Here's the original framework:

Done well, 5S improves safety, quality, and morale while reducing time wasted hunting for tools or information.

Adding a 6th S: Safety

Some Lean purists resist adding more S's. I disagree.

Safety isn't an "extra". It's a core responsibility. The 6th S serves as a constant reminder to:

- Identify hazards during every 5S activity.

- Correct unsafe conditions before they lead to incidents.

- Design improvements that prevent injuries, not just defects.

- It sends a powerful message that lean is not just about profits and that we care for everyone.

When Safety is explicit, teams naturally build it into every decision.

Adding a 7th S: Scan

Before the first label is printed or the first tool is moved, I ask teams to Scan the area. Think of it as a disciplined pre-game:

- Boundaries: Define exactly which area is in scope.

- Data Gathering: Measure current conditions: inventory levels, equipment uptime, walking distances.

- Visual Evidence: Take "before" photos and create spaghetti diagrams to track motion and material flow. Tip: Make sure you mark the spot where each picture is taken from. You will want to take the "after" pictures from the same spots.

- Safety Review: Note hazards, near-misses. Involve the employees in the area and members of the safety committee.

Scanning grounds the team in facts. When the 5S event is done, you can show clear before-and-after results, making improvements easier to sustain.

From 5S to 7S: A Practical Evolution

I am personally less concerned about preserving tradition than I am about making the work better.

Adding Safety and Scan strengthens 5S by:

- Protecting people first.

- Ensuring improvements are based on real data.

- Building a record that proves the impact of your efforts.

Takeaway: Start with the classic 5S. Then add Safety and Scan to make sure every event protects your people and captures the facts before you improve.