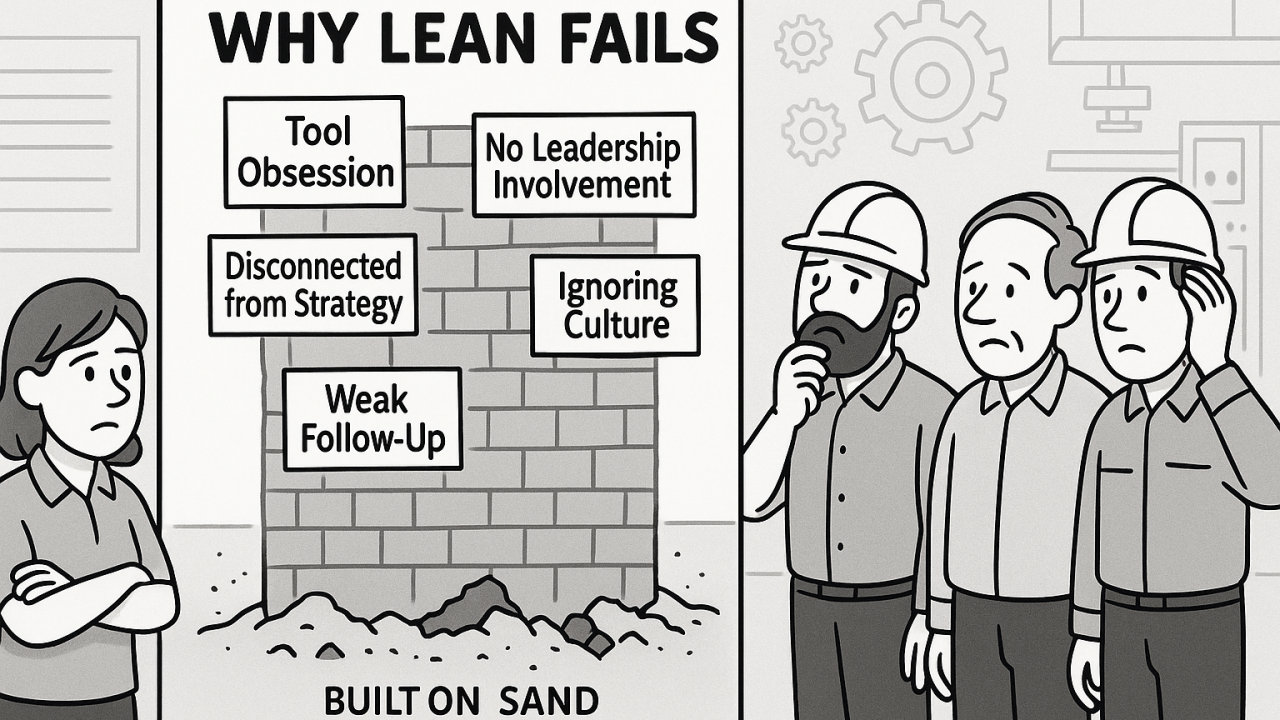

5 Signs Your Transformation Is Built on Sand

October 20, 2025

We often find companies proudly displaying their Lean certification plaques in the lobby. They usually have Kanban boards, 5S audits, value stream maps, and all the visuals. A particular company comes to mind.

In this company, within minutes on the shop floor, we could tell something was off. People were doing "Lean activities," but no one could explain why. When I asked a supervisor what problem a recent Kaizen event had solved, he shrugged and said,

"We just do them every quarter because it's part of the program."

That's when we realized: they had built their Lean transformation on sand.

1. The Tool Obsession Trap

Many companies fall in love with Lean tools but skip Lean thinking. They install 5S, Kanban, SMED, and Kaizen events. Yet they forget that these are just means, not ends.

Tools don't create improvement; people do. Without purpose, tools become theater.

Ask yourself: Do our Lean activities solve problems, or do they just check boxes?

2. No Leadership Involvement

If leaders don't walk the talk, Lean dies quietly. When executives delegate improvement to consultants or to "the Lean team," it sends one clear message: "This is someone else's job."

Lean only works when leadership models it, when they show up on the floor, ask questions, and remove barriers. Transformation doesn't happen in conference rooms. It happens where the work is done, at the Gemba!

3. Disconnected from Strategy

Many organizations treat Lean like an add-on rather than the way they achieve goals. They chase local improvements with no alignment to what matters most for the business.

The result? Islands of success in a sea of confusion. True Lean connects every improvement to the company's strategy, from vision to daily actions. That's where engagement and results multiply.

4. Ignoring Culture

Culture is the foundation of Lean. If people fear blame, don't trust leadership, or feel their ideas don't matter, no amount of tools will fix it.

You can't "train" your way into culture. You build it through respect, recognition, and daily consistency. Every interaction either reinforces the culture you want, or the one you don't.

5. Weak Follow-Up

The fastest way to kill enthusiasm is to ignore the results of people's efforts. When employees see their ideas vanish into a black hole, they stop contributing.

Lean thrives on feedback loops: celebrating wins, fixing what didn't work, and learning as a team. If you want continuous improvement, make the "continuous" part visible.

Building on Rock, Not Sand

Lean fails when it's treated like a project. It succeeds when it becomes the way you think, lead, and solve problems.

A strong Lean transformation is built on three pillars:

- Purpose: everyone knows why improvement matters.

- People: everyone participates.

- Persistence: improvement never stops.

If you build on those, Lean stops being an initiative and becomes your organization's competitive advantage.

Which of these five traps do you see most often in your organization?

#ManufacturingSimplicity #LeanTransformation #OperationalExcellence #Leadership #ContinuousImprovement #Culture #StrategyDeployment #Lean